Wonder how we make our race medals? Come and Learn! Our case studies also highlight special projects to show you our manufacturing process.

Virtual Mockup

Upon receiving the artwork from customer, we process the artwork and will produce a virtual mockup like this one so you know what your final medal could look like. Here is the time to correct any typos or positioning errors!

Mold

Once the virtual mockup is approved, We start with zinc alloy, using the customer’s artwork to make a mold. Think about it like a rubber stamp, it will be used to stamp the medals later on.

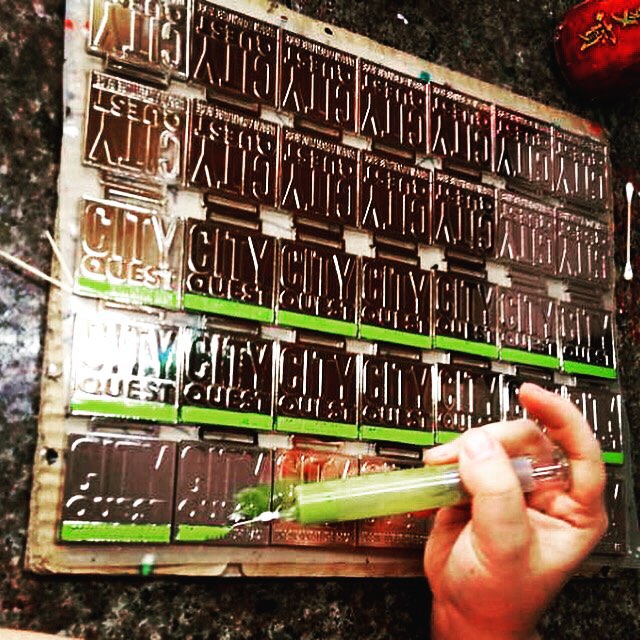

Stamping

Using the mold, medals are stamped out, this process is mostly done by machine, and here are how ‘virgin’ medals look. They still need a lot of work!

Polishing

Virgin medals do not have the polished, smooth surface that we normally would see. They are mostly polished by hand, one by one.

Electroplating

There are many plating colors available for running medals. Our medal plating chart has a list of our standard and most popular colors. The plating will give the metal color that is expected. Shiny and matte medals are great with enamel color fills, which is the next step. If the medal do not have color fills, antique finish will work best as it will show all the small details and text wonderfully.

Enamel Color Fill

Here is where the magic happens! The marvelous colors are filled in one by one, manually and meticulously. High level of skills and experience is required for this stage. When all the colors are filled, the medals are left to dry out.

Race Ribbon

Finally the ribbons are cut and sewn onto medals. Check out all our ribbon printing and ribbon attachments options. The race medal is finally finished!

Sample Medal

Sometimes a medal viewed on virtual mockup can be drastically different from the computer screen to actual medal. The enamel fill color can may sometimes be not what you expect. Sample medal is an important step in the manufacturing process for this reason. A few medals are stamped from the mold, then polished, filled with color. They are then sent by courier or emailed to the customer so you the customer know exactly how your final products will look. Minor adjustments, colors can be adjusted and tweaked until it is perfect. That’s how we make our race medals